ARRA

Supporting facilities for kitchen sets with modular, clean and organized concept

2020

Role

Industrial product designer

Timeline

6 months

Tools

Inventor & Corel Draw

Reading time

5 min read

Overview

This product was made in order to complete a final assignment in the Industrial Product Design major. The type of product chosen is furniture, while the issues raised are common problems in Indonesian kitchens.

The Challenge

Supporting facilities that are placed on the wall are less than optimal in accommodating various kinds of cooking equipment. In addition, water from freshly washed cooking utensils can drip directly onto the worktop without any resistance.

Supporting facilities that are placed above the worktop make the worktop work area smaller. This is due to the unbalanced type and capacity of supporting facilities with the equipment used.

Approach

The product’s design process uses observation, shadowing and in-depth interview research methods. The data obtained is processed into affinity diagrams and user personas. The method used in making the product is form follows function.

Output

Design product supporting facilities (modular shelves) for activities on the worktop kitchen set with a clean and organized concept

Research

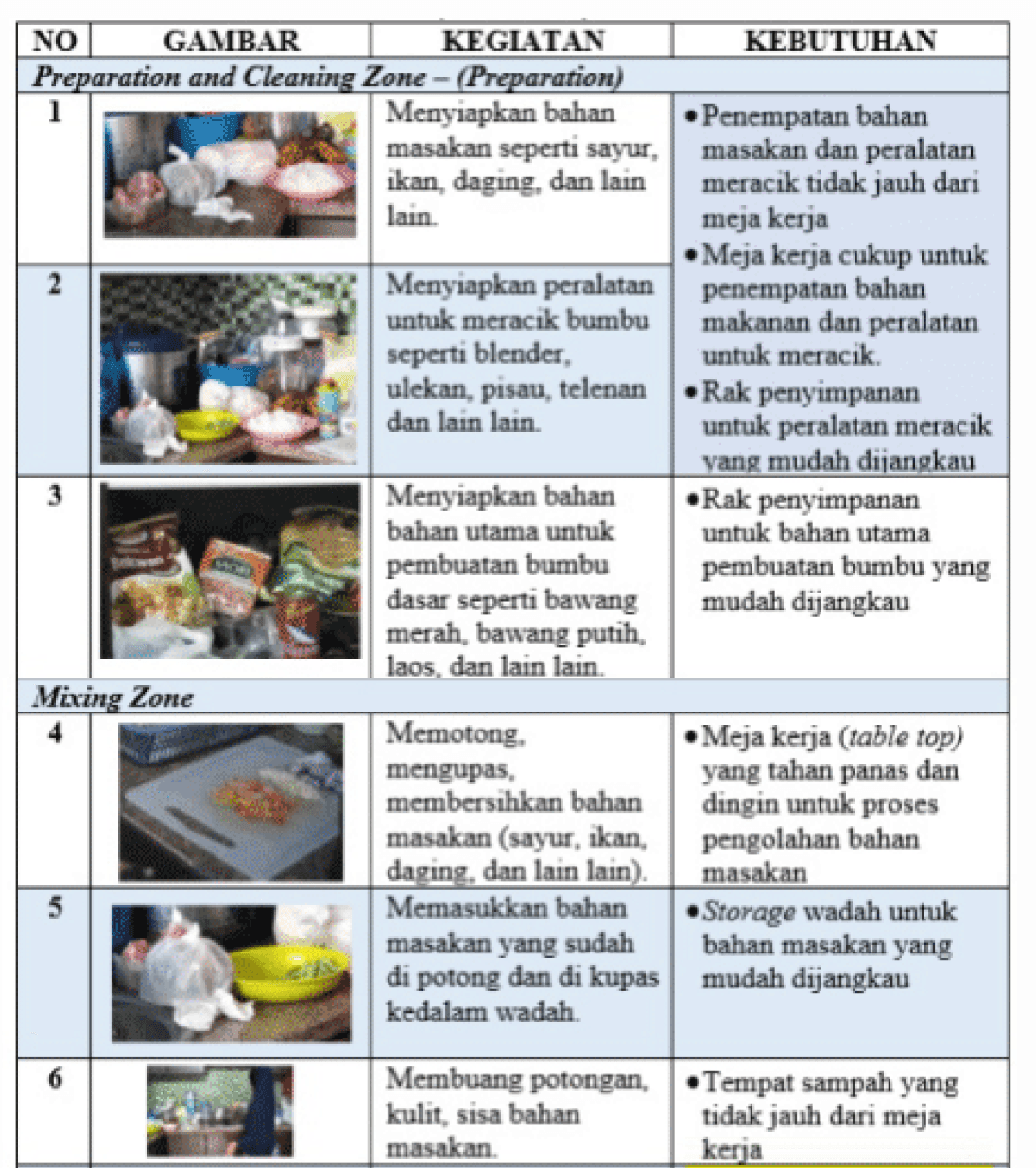

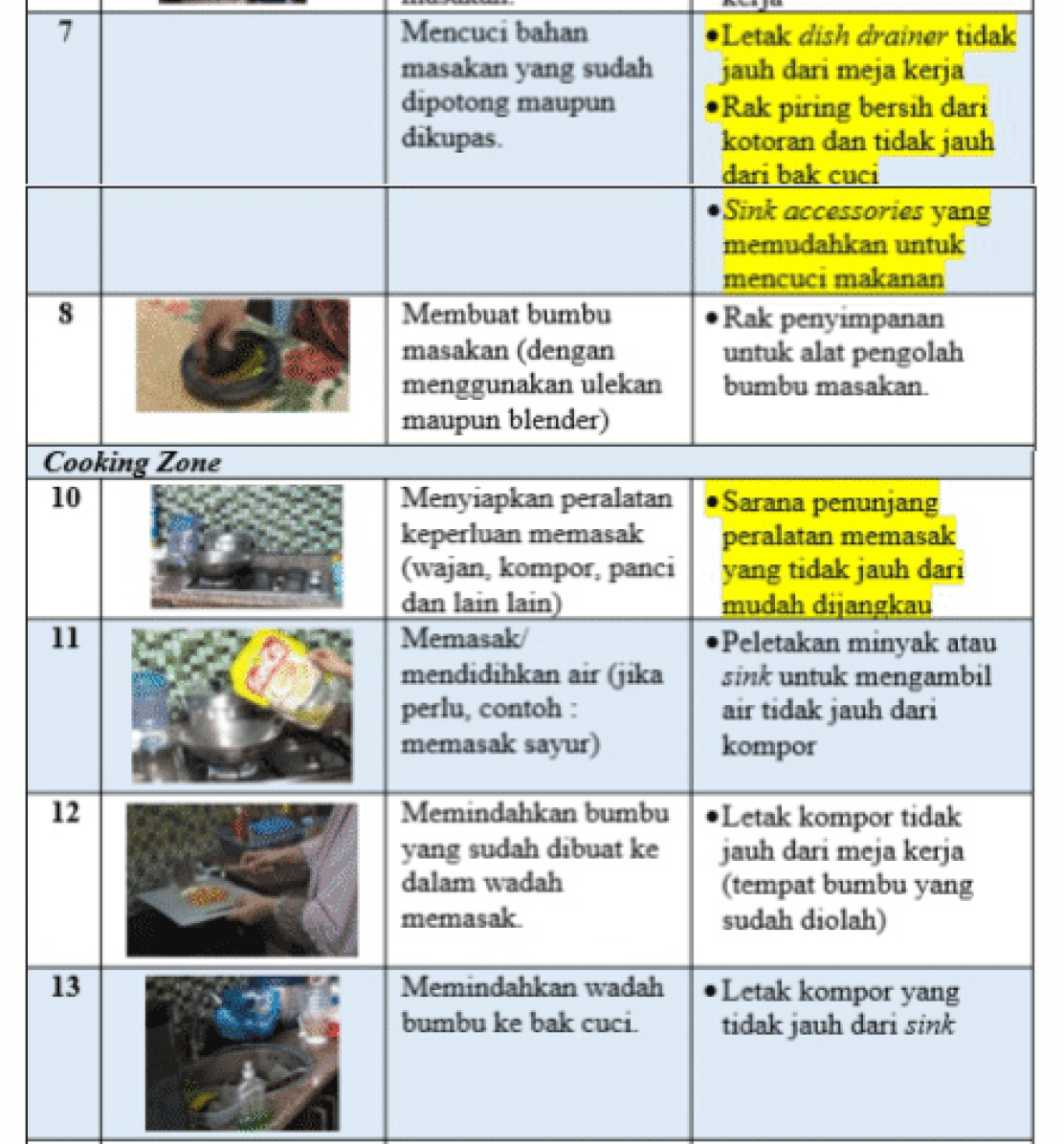

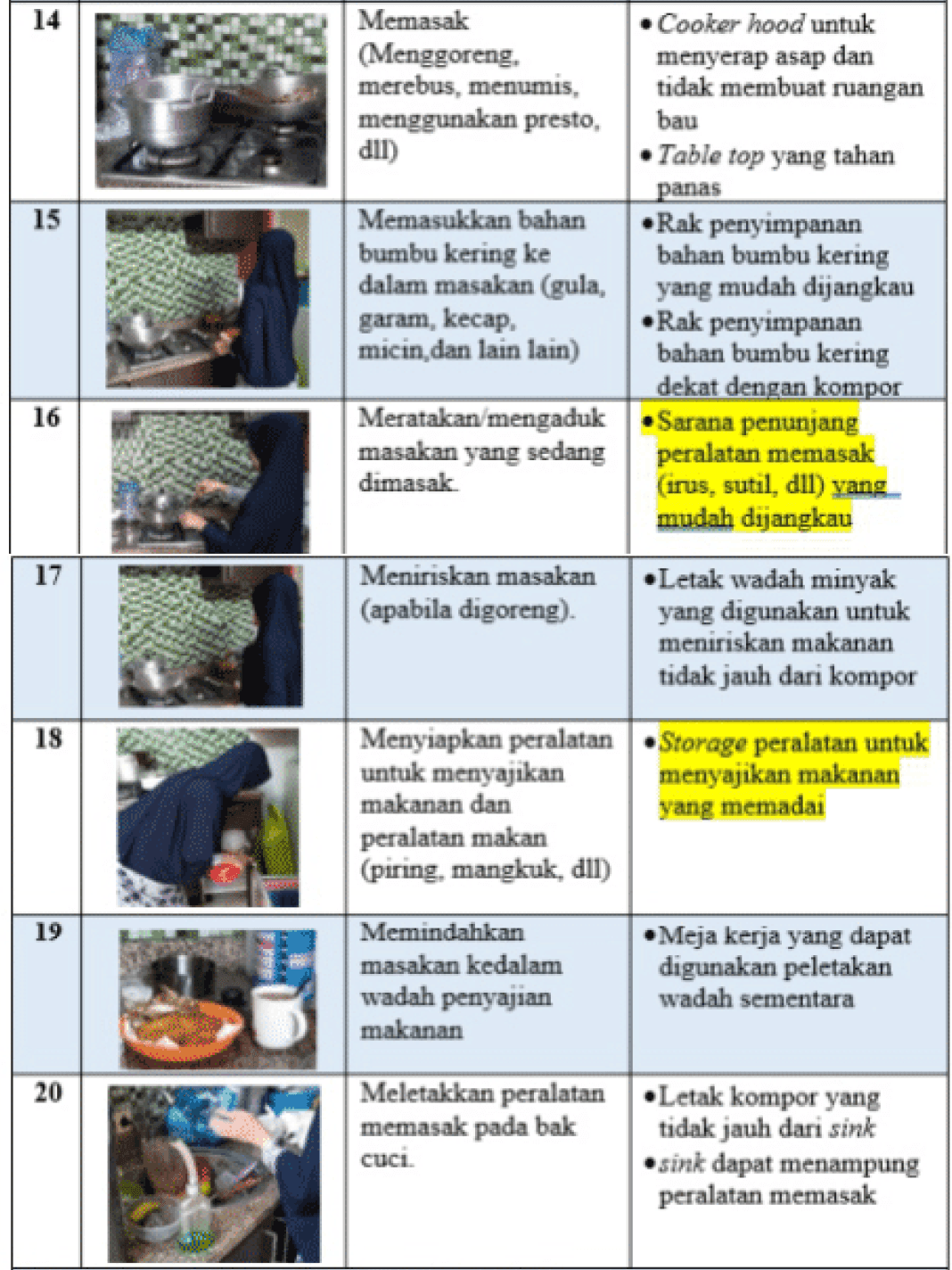

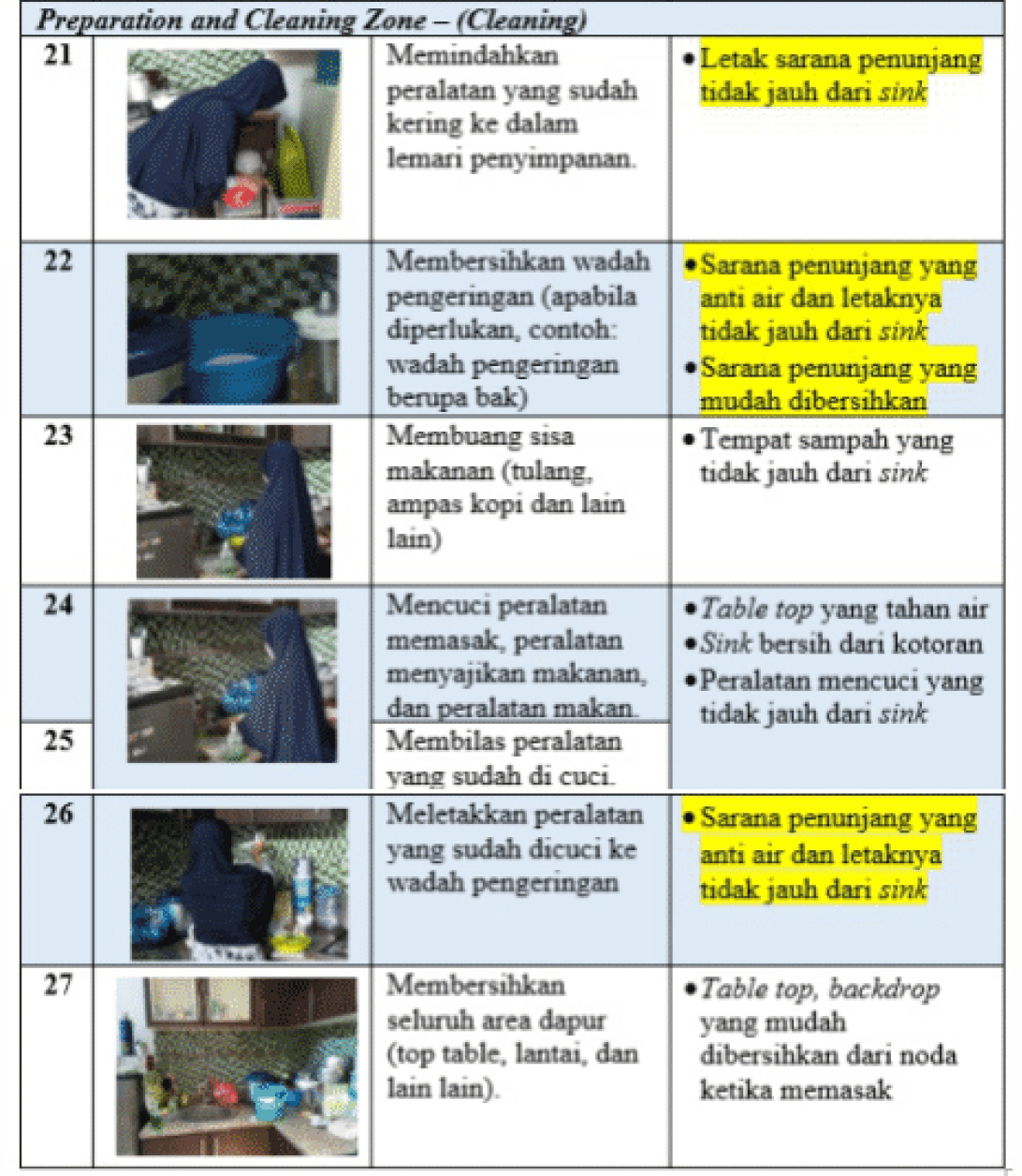

The research process was carried out using the shadowing method and in-depth interviews. Through these two methods, the needs of each sub-activity are generated when the user is in the kitchen.

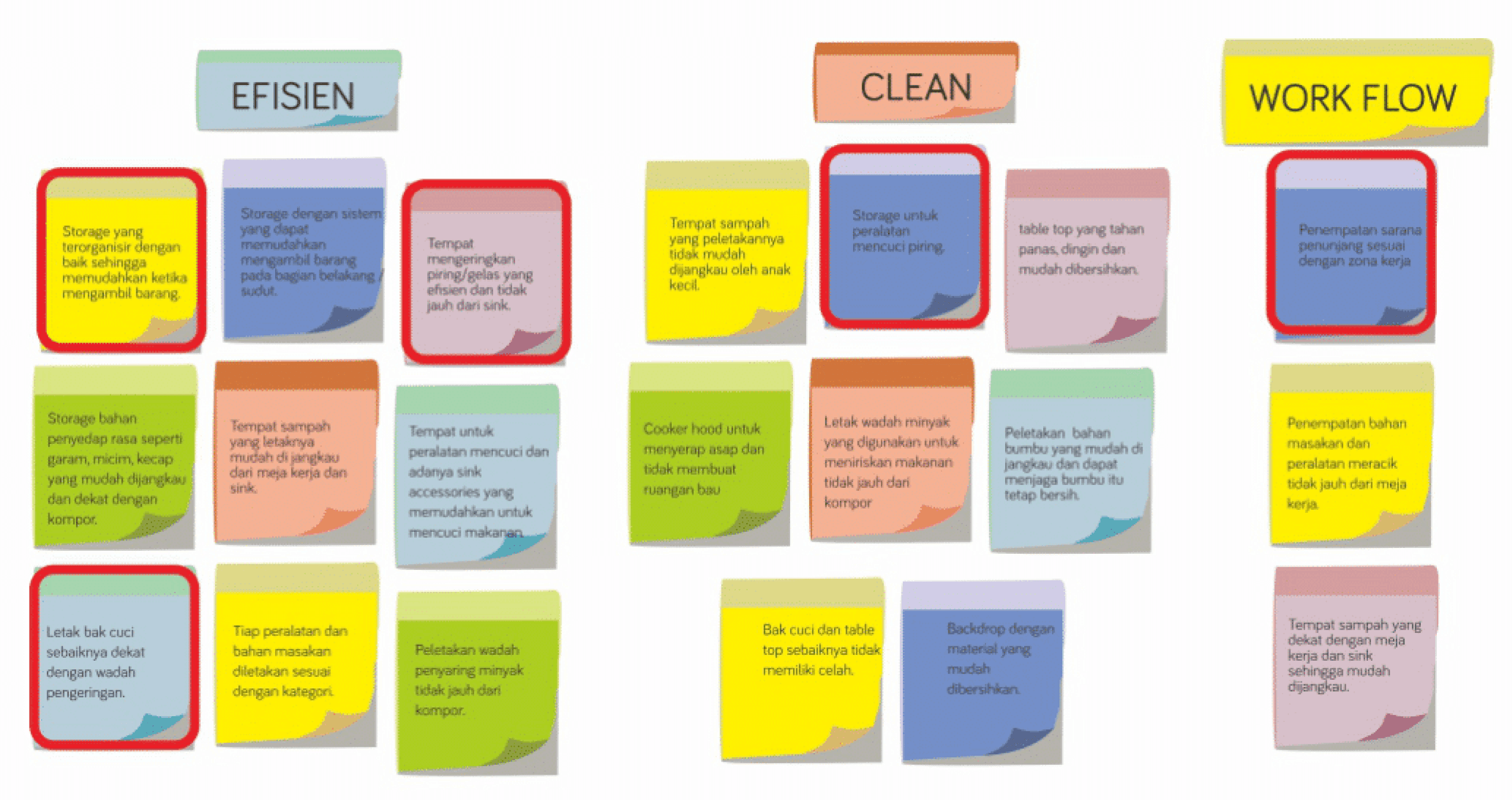

Study and Analysis

At this stage, I process the interview data into an affinity diagram to find the main needs of the user. Apart from that, I also conduct an analysis of activity studies, needs, quantity and volume of goods, frequency of use, accessibility, psychographics and persona, anthropometry, layout, and branding.

Konsep Desain

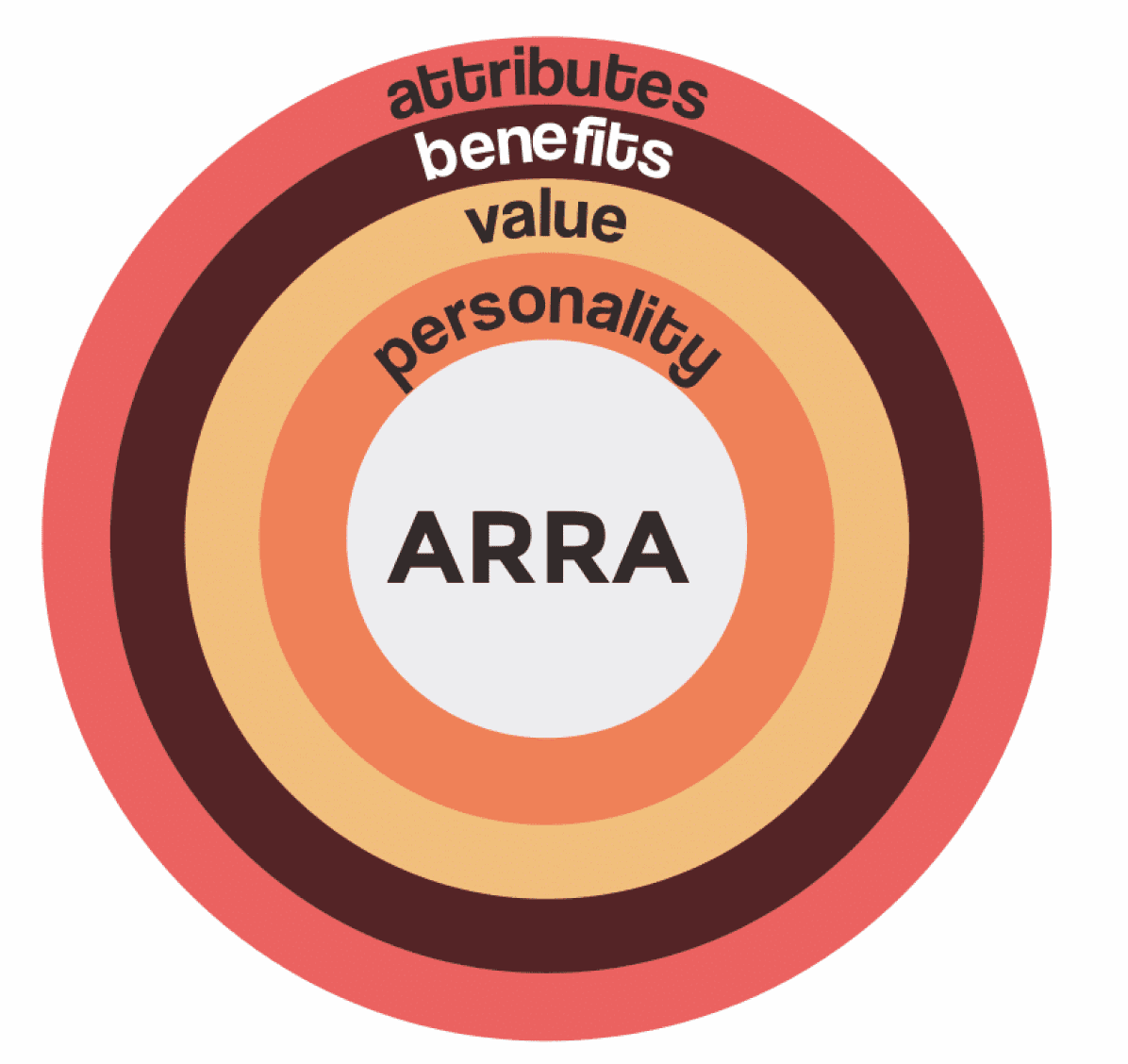

The supporting facility for cooking activities with shelf products is named Arra with a clean and organized concept. Made of steel and plastic which makes the product durable. In addition, this modular product can beadjust to the needs of each user.

Steel

Plastic

Organize

Clean

Modular

Functional

Efficient

Easy to assembele

All in one organizer

Long lasting

Compact

Space saving

Name: Anisa Puspitasari

Age: 25-36

Job= Employee

Salary= 5.500K

Character: Woman nimble and multitasking

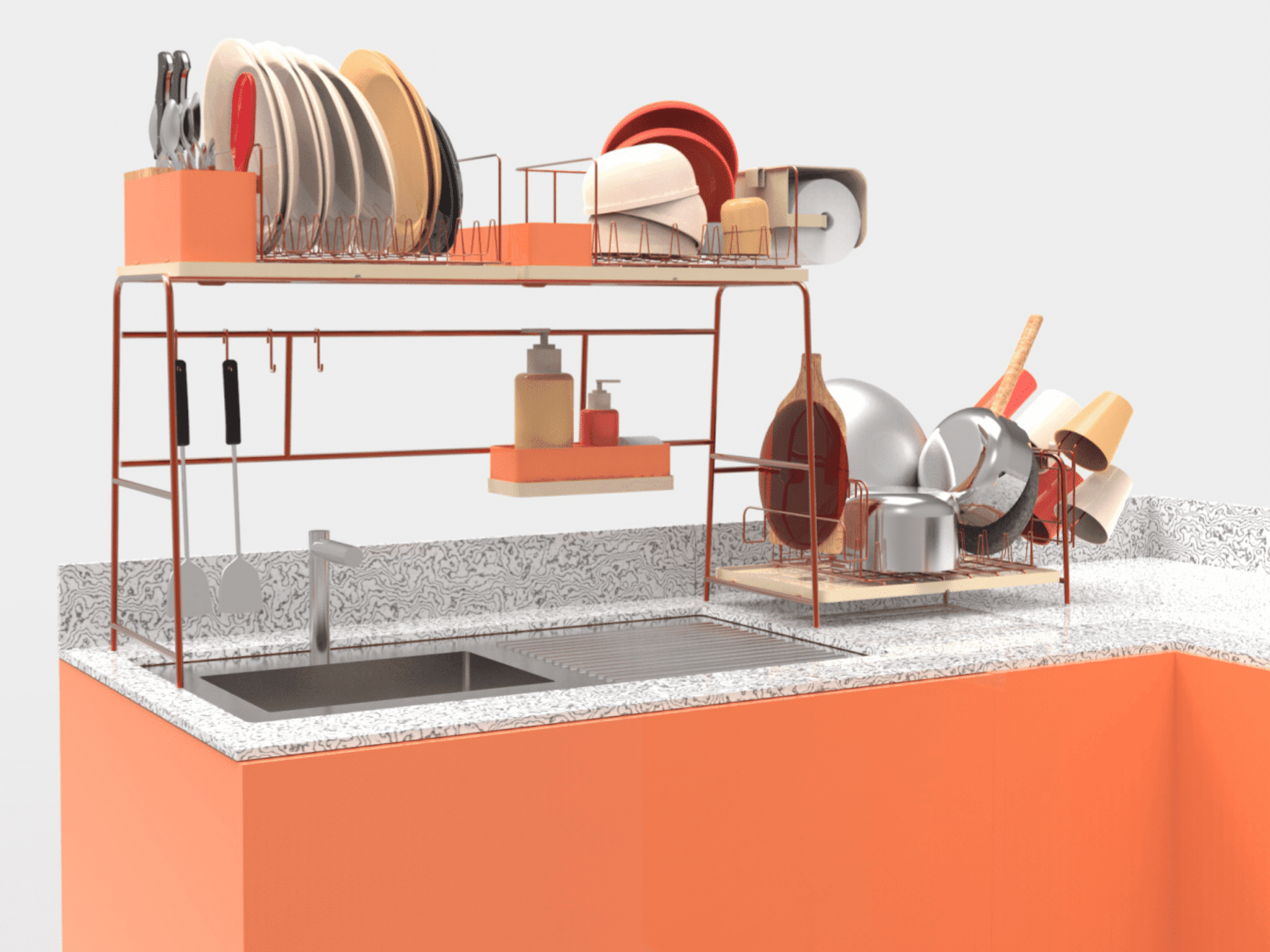

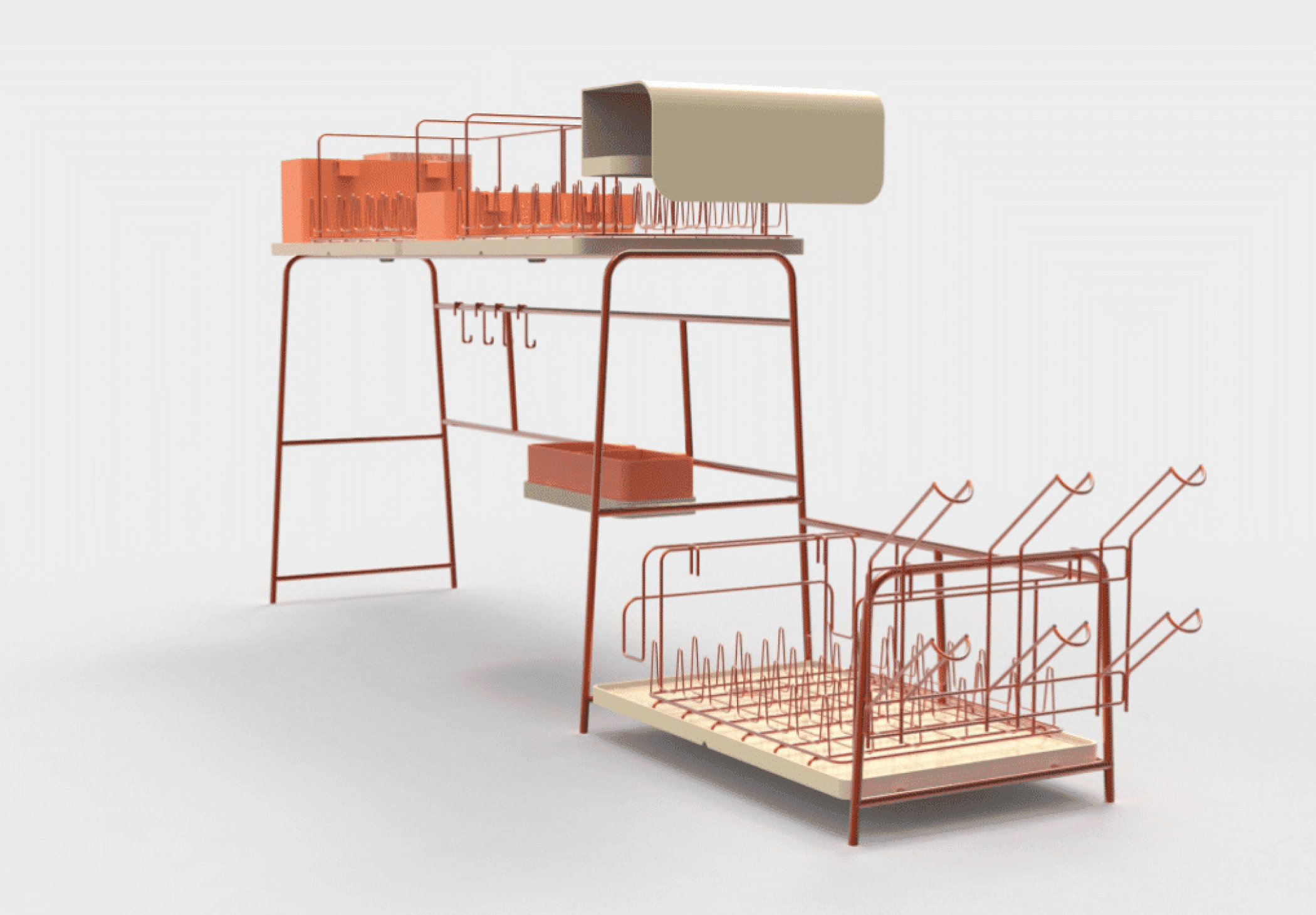

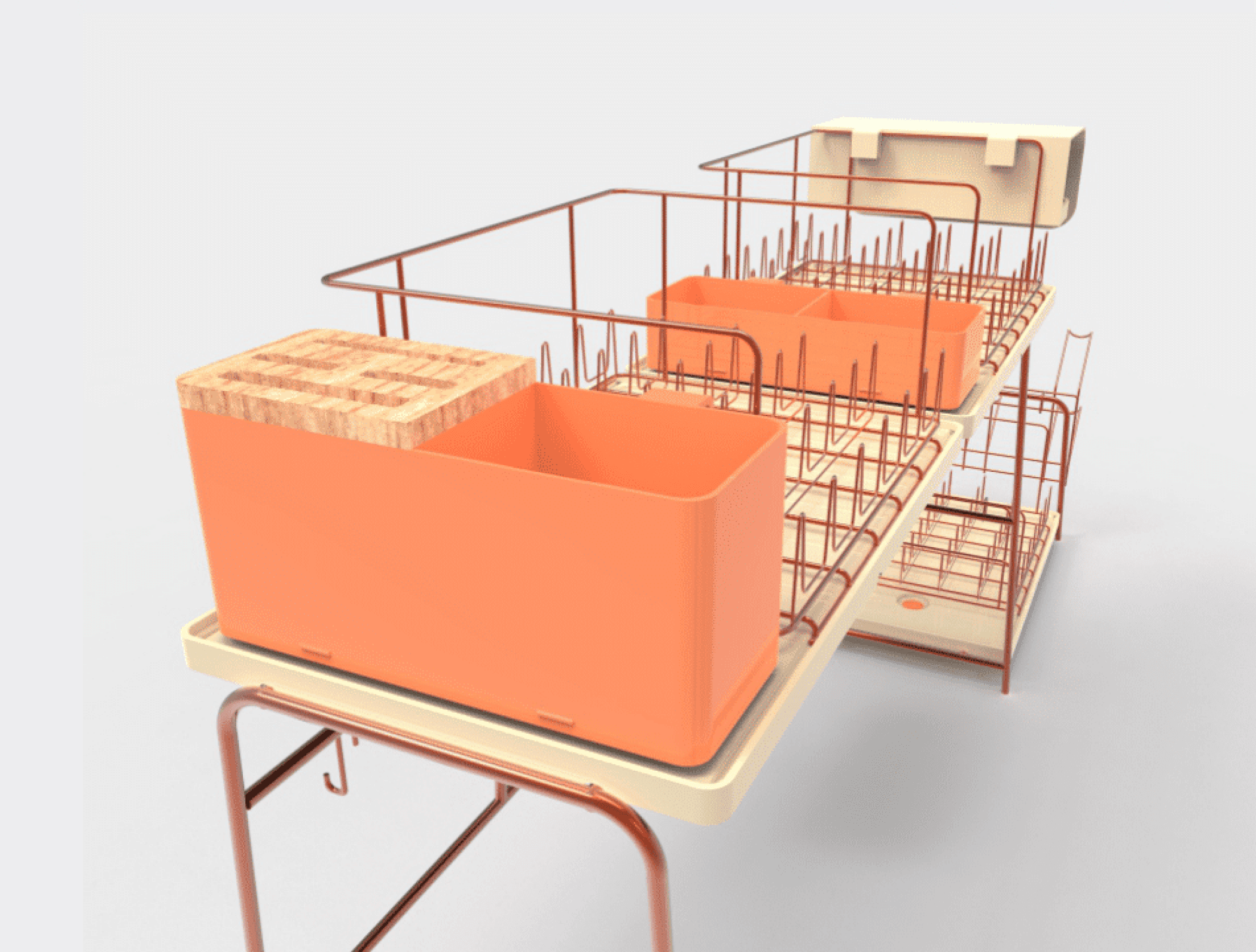

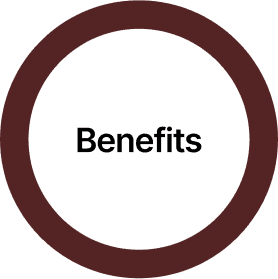

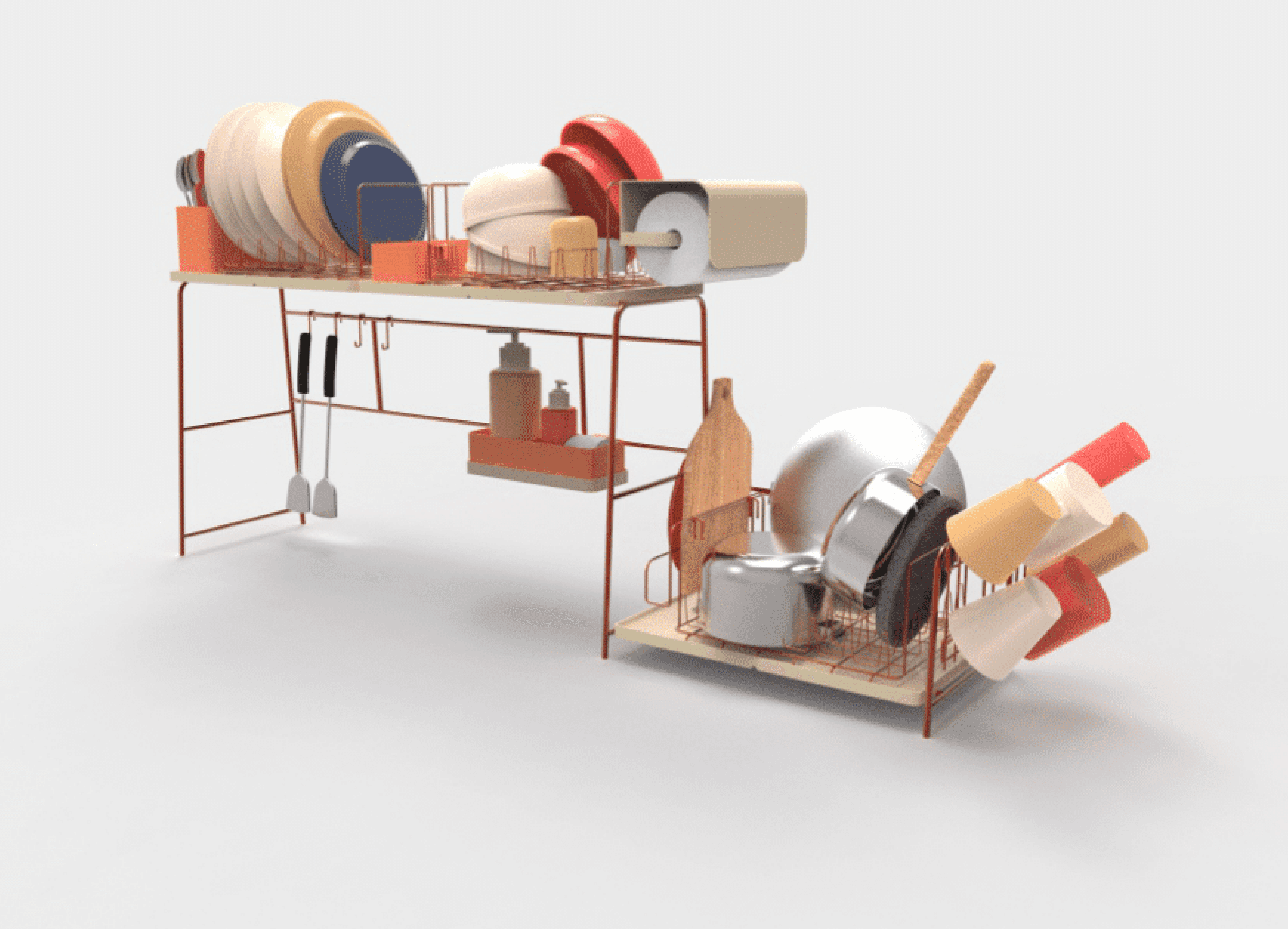

ARRA is supporting facilities for activities on a worktop kitchen set in the form of a shelf. This rack consists of several modules that can be arranged and used as needed and can even be placed above the sink. ARRA functions to organize the equipment used for activities on the kitchen set so that the equipment is neatly arranged and not easily damaged.

CLEAN

Shelves are easy to clean. In addition, this shelf design has good air circulation and good material to avoid moisture problems that exist in Indonesia (mouldy).

ORGANIZED

Shelves can organize the equipment in it with the modules provided. So that the workflow and efficiency of activities on the worktop kitchen set are more efficient.

ARRA

Easy to clean

The module cleaning process is carried out by easily removing the module latch. After washing, the module can be used immediately without waiting for it to dry.

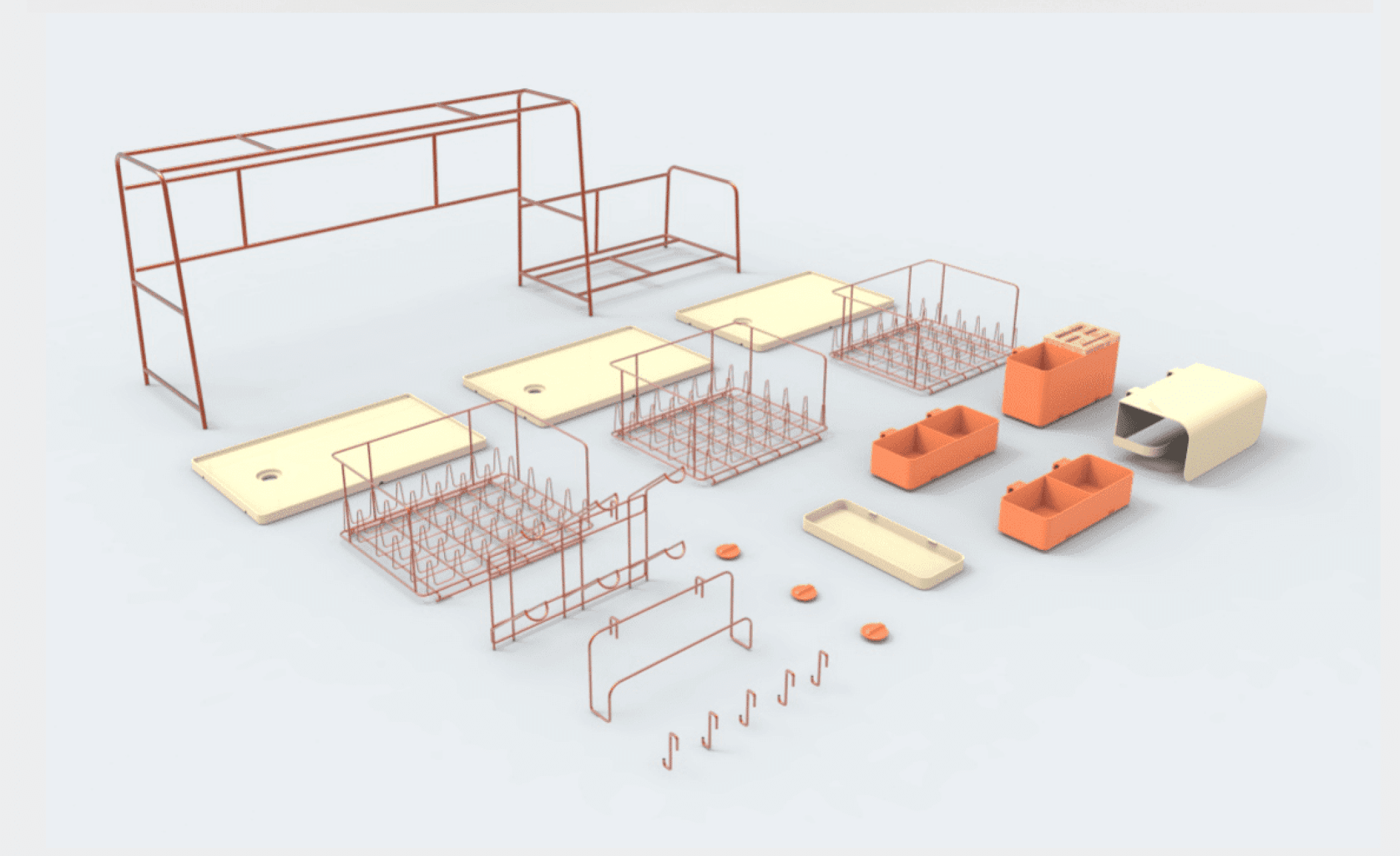

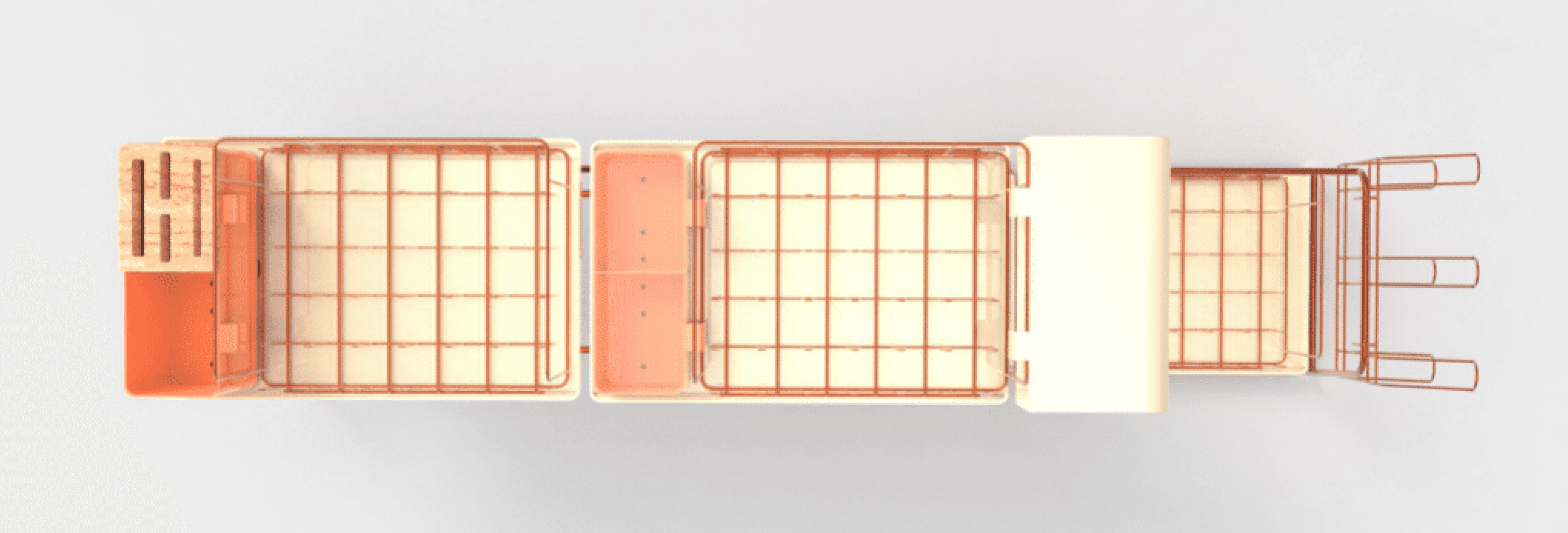

Compact Packaging

Because it is modular, the existing modules can be arranged in such a way as to form a concise packaging. The size of this shelf packaging is 980 mm x 380 mm x 180 mm.

Easy to assemble

The process of assembling the base module uses the L key so that the user can do it himself. while for the installation of the module on the base module, it is done by linking the module.

All in one organizer

Equipped with various modules that can accommodate small equipment (cup lids) to large equipment (pans, etc.).

Space lots of it

Has a size of 120 cm with a height of 46 cm. There is a lot of space that can be used to put things.

Long lasting durability

The strong steel material makes this shelf last a long time. Air circulation for this shelf is smooth enough so there is minimal risk of mold.

Takeaways

Here’s what was working

A modular system that is easy to assemble and helps users meet their needs according to the cooking or eating utensils they have

Selection of materials suitable for the humid climate in Indonesia

Compact packaging that facilitates product delivery over long distances

Here’s where we need continued iteration

Exploration of materials that are lighter and allow for mass production in Indonesia (such as plastic, recycled materials and others)

There is a need for testing or simulating the strength of the product to hold the load with the type of lock (lock between modules) used. To ensure that this product can indeed withstand the appropriate load

Leason Learned

The process of making this design is the most memorable design process for me. In addition to the process of brainstorming and discussions with supervisors not being easy, the process of finding craftsmen to execute existing designs is also an unavoidable challenge.

This design could not be executed according to plan because of the lack of steel craftsmen in Surabaya. In the end, this design underwent many changes and was developed into several other alternatives before finally being executed.

Made with

in Jember